HIGH-PERFORMANCE DESIGN AND TECHNOLOGY

FOR ALUMINIUM PRODUCTS THAT TAKE CENTRE STAGE IN CONTEMPORARY DESIGN

The experience we have gained over the years, combined with our ongoing investment in technology and production machinery, enables Indinvest LT to meet the constantly changing technical and quality requirements of the market.

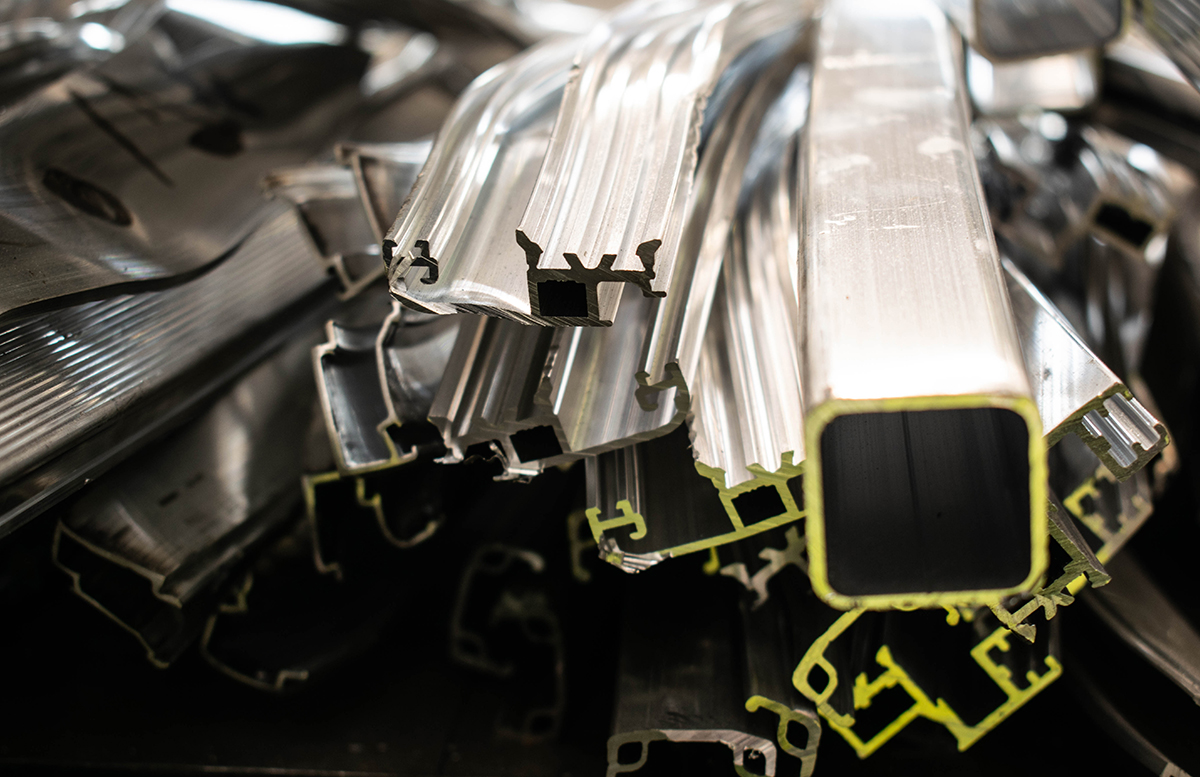

Indinvest LT specializes in the extrusion of aluminium alloys and the manufacture of bespoke profiles. Our extrusions are used across every sector, from automotive to mechanical engineering, HVAC, transport, architecture, furnishing, lighting design, the marine industry, sport, etc.

Technical liaison with the customer at every stage of the production process, and partnerships with the best die manufacturers, enable the company to deliver outstanding product quality and all-round customer satisfaction.

THE SHAPE OF IDEAS

Extrusion is a process of transformation by high-temperature mechanical deformation, for the manufacture of profiles to customer designs and specifications

Indinvest LT has 5 extrusion lines: one 5” 1100 tonne press specifically for the production of microprofiles; one 7” 1800 tonne press, two 8.5” presses, of 2500 and 2800 tonnes respectively, and one 10” 3500 tonne press. Our systems enable us to extrude profiles with weights of up to 22 kg/m, lengths of up to 14 meters and mechanical characteristics that meet the requirements of various sectors, from commercial to automotive.

Indinvest LT can also take care of all the subsequent finishing and surface treatment processes, thermal-break assembly, cutting to size, special machining processes and customized packaging, to offer its customers a comprehensive service.

PRODUCTION OF EXTRUDED PROFILES

> 60,000 tonnes per year

PROFILE TYPE

Weight:

Bar length:

Maximum extrusion dimensions:

25 g/m to 22,000 g/m

max. 14 m

rectangular profiles, 400 mm x 40 mm approx.

square profiles, 195 mm approx.

round profiles, diameter 250 mm approx.

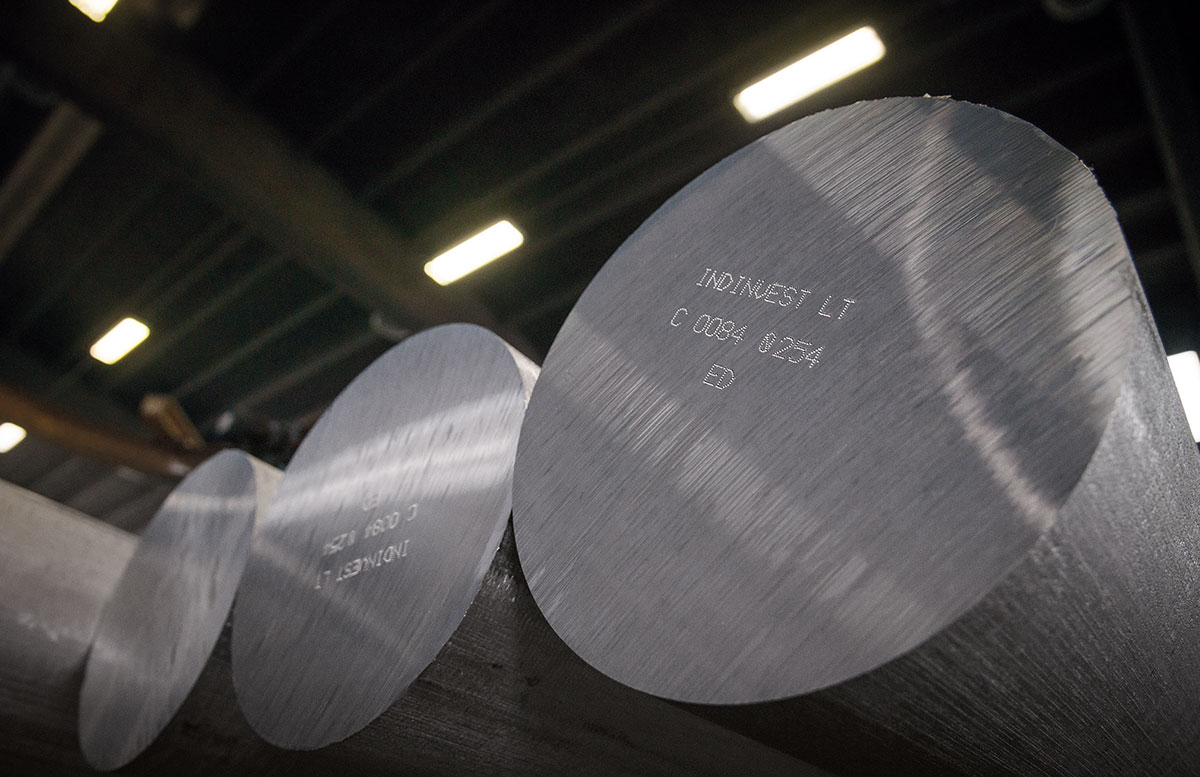

NEW LIFE, NEW FORMS

Indinvest LT has its own integrated foundry, so is ideally placed to produce custom alloys, while ensuring continuous availability of raw material and the right balance between the alloy to use for extrusion and the mechanical and surface characteristics that customers require of their profile sections.

The major advantage of being both extruders of aluminium profiles and producers of raw material lies in the continuous exchange of know-how between the technicians in our extrusion and foundry departments, who collaborate to maximize finished product quality.

The foundry is fully equipped with advanced energy saving technologies. In close collaboration with the best research organisations, Indinvest LT has made significant advances in the recycling of pre- and post-consumer scrap aluminium, thus enabling us to produce high-quality secondary aluminium alloys.

BILLETS FOR A CIRCULAR ECONOMY

THE CIRCULAR ECONOMY IS A SELF-REGENERATING ECONOMIC SYSTEM INVOLVING THE RE-USE OF MATERIALS IN SUCCESSIVE PRODUCTION CYCLES, TO MINIMIZE WASTE AND PROMOTE ECO-SUSTAINABILITY.

Corporate social responsibility for the environment and energy saving has finally become a reality, which is stimulating creative design and driving product innovation towards an ever greener future. Indinvest LT has taken this opportunity to develop a new philosophy aimed at harnessing the full potential of aluminium in the circular economy. Aluminium is already a vital metal, used for creating a wide range of products and materials that make a major contribution to a greener future. This is the thinking behind CREAL, a billet containing over 85% post-consumer recycled aluminium, obtained using the industry’s most advanced scrap sorting and melting technology. This recycled content, amounting to 85%, is aluminium that has reached the end of its useful life in its original incarnation, and has been channelled back into the production circuit. The higher the recycled content, the smaller the carbon footprint. Using aluminium profiles made from CREAL billets is a direct path to green design.

THINK GREEN ……THINK CREAL

RECYCLED SECONDARY ALUMINIUM PRODUCTION (BILLETS)

> 60,000 TONNES PER YEAR

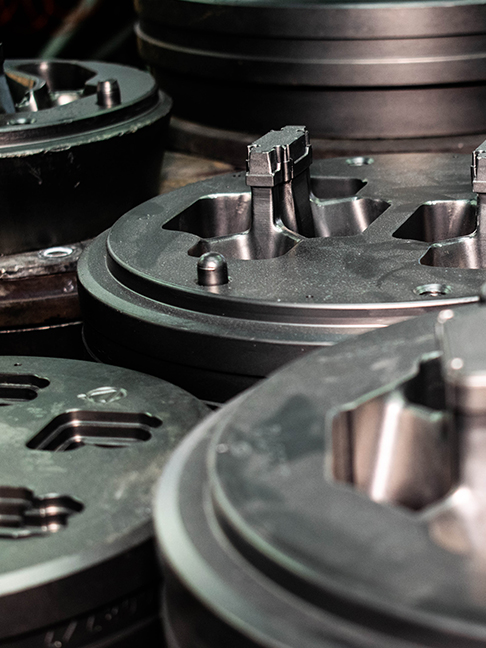

TECHNOLOGY AT THE SERVICE OF FORM AND FUNCTION

Our business is about much more than manufacturing aluminium profiles: it’s about achieving real customer satisfaction.

Over the years, Indinvest LT has chosen to support its customers as far as possible by offering services beyond simple extrusion. The company can therefore supply machined profiles with a range of surface treatments.

Nature teaches us that form follows function.

We add technology and ingenuity to make this happen and evolve to new aesthetic and mechanical standards, through the innate understanding and passion that we have cultivated together over time.

ADDITIONAL PROCESSING

SURFACE FINISHES

Oxidation

Painting

MACHINING

Bending

Tumble finishing

Blanking

5-axis CNC machining centres

Cutting to size

Threading

Drilling

Milling

PROFILE ASSEMBLY AND ROLLING

Assembly of thermal-break profiles

Mechanical pre-assembly

PACKAGING

Special and custom packaging

UNCEASING ATTENTION TO DETAIL

Indinvest LT’s know-how covers every stage of profile processing, from alloy production to technical analysis of profiles, design of dies in conjunction with die suppliers, extrusion, storage, technical service, sourcing and delivery of material.

The experience we have gained over the years, combined with our ongoing investment in technology and production machinery, enables us to meet the constantly changing technical and quality requirements of the market. Constant control of all the tests, analyses and operations we methodically conduct on all materials and equipment, plus the added value of our undisputed professionalism, ensure that Indinvest LT products meet the highest standards of quality.

Building a successful company requires investment, machinery, equipment and advanced technologies; but above all, it requires effective organization, professionalism, skill, talent and personal involvement. These are a company’s biggest assets, and at Indinvest LT they can be found in abundance at every level, from top management to factory floor.

INDINVEST LT offers a wide range of products

to meet every PROJECT requirement in EVERY AREA OF APPLICATION

Furnishing

STRUCTURAL PROFILES, PROFILES FOR CABINET DOORS, SLIDING SYSTEMS FOR CABINET DOORS AND DRAWERS, HANDLES, COMPONENTS

Automotive

STRUCTURAL PROFILES, MOULDINGS, TRACKS FOR SLIDING ROOFS, SLIDING SEATS, ETC., MECHANICAL COMPONENTS MADE OF VARIOUS ALLOYS

Cycles

WHEEL PROFILES

Industry

COMMERCIAL PROFILES FOR A FULL RANGE OF REQUIREMENTS AND APPLICATIONS

Construction

PROFILES FOR STANDARD AND THERMAL-BREAK DOOR AND WINDOW SYSTEMS, CURTAIN WALLS, ACCESSORIES FOR DOORS AND WINDOWS, CONSTRUCTION COMPONENTS

Photovoltaic

SUPPORT AND FIXING SYSTEMS, FRAMES, CORNICES

Lighting

HOUSINGS AND COMPONENTS FOR LUMINAIRES, CONTINUOUS LIGHTING SYSTEMS, COMPONENTS

MECHANICAL ENGINEERING

VARIOUS COMPONENTS MADE OF SPECIFIC ALLOYS FOR MACHINING

COMPRESSED AIR

PUMP HOUSINGS AND VALVE BODIES, COMPRESSED AIR DISTRIBUTION SYSTEMS

Scaffolding

STRUCTURAL PROFILES, UPRIGHTS, STEPS, GANGWAY SYSTEMS

blinds

STRUCTURAL PROFILES, ARMS, TRACKS, CASINGS, FASTENING ACCESSORIES

Ventilation

SYSTEMS FOR AIR CONDITIONING INSTALLATIONS, SHUTTERS, AIR DISTRIBUTION GRILLES, FAN AND IMPELLER BLADES, HEATERS